Develop Equipment Maintenance Logs Protocol for Manufacturing

Objective:

– Draft a standardized protocol for maintaining equipment maintenance logs in a manufacturing plant.

– Ensure accurate record-keeping of maintenance activities, breakdowns, and repairs.

– Improve equipment reliability, reduce downtime, and optimize maintenance costs.

Description

Expected Inputs:

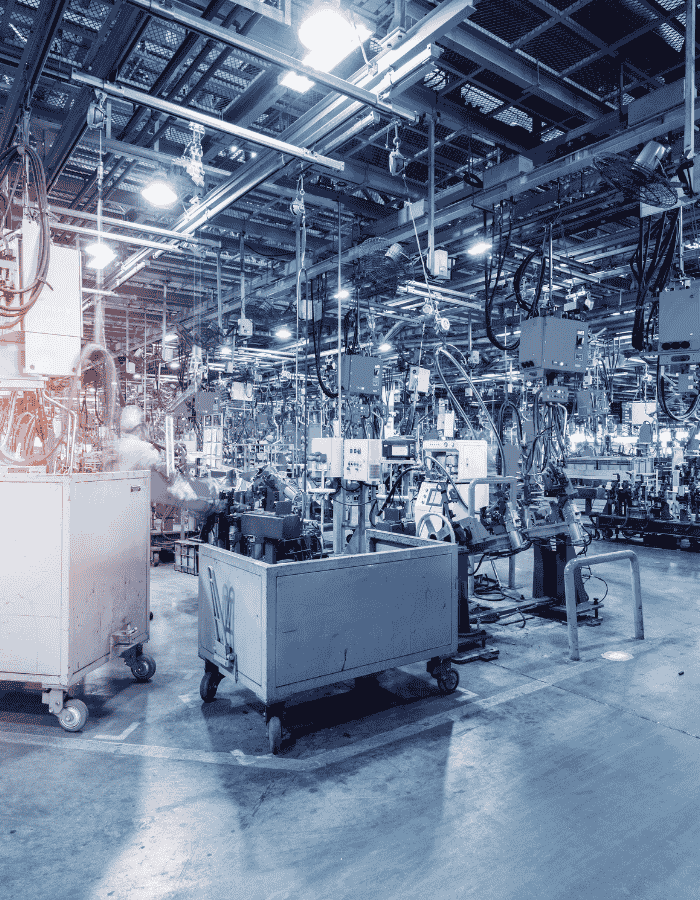

– [Manufacturing_Plant_Type: e.g., Heavy machinery, Electronics assembly, Food processing, Pharmaceuticals]

– [Key_Equipment_Types: e.g., Production lines, CNC machines, Conveyor systems, HVAC units, Forklifts]

– [Key_Data_Points_to_Log: e.g., Date/Time of maintenance, Type (preventive/corrective), Description of work, Parts replaced, Technician, Downtime duration, Cost, Root cause of failure, Next scheduled maintenance]

– [Desired_Outcome_of_Protocol: e.g., Reduced unplanned downtime by 10%, Extended equipment lifespan, Improved maintenance scheduling accuracy, Lower repair costs]

– [Maintenance_System_Used (optional): e.g., CMMS (Computerized Maintenance Management System), Manual logs, Spreadsheet]

Results:

– A detailed protocol outlining the process for creating, updating, and utilizing equipment maintenance logs.

– Standardized log templates with all required data fields.

– Procedures for recording preventive maintenance, routine inspections, and emergency repairs.

– Guidelines for data entry accuracy, accessibility, and reporting.

– Integration with inventory management for spare parts.